A 55-gallon drum is a large, cylindrical container that is capable of containing 55 gallons worth of a substance. Primarily, 55-gallon drums are used for storage and shipping of bulk goods. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

Since 1947, General Container has specialized in a mixture of 55 gallon drums, a full line of boxes, shipping supplies and thousands of other industrial packaging and container products. This industry leader has the market's most knowledgeable customer service reps, a vast product offering, no minimum order, online ordering and volume discounts. Contact us today for more information.

Since 1918, James T. Warring Sons has been distributing new and reconditioned industrial drums, steel drums, fibre drums, plastic drums and industrial containers. We also offer plastic barrels and other products for nursery applications, as well as oak kegs and barrels for the winery industry.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

More 55 Gallon Drum Manufacturers

Drums vs. Barrels

The terms “drum” and “barrel” are often used interchangeably, as both can be made from metal, fiberglass, or plastic and serve to transport goods and other substances. They come in various standard sizes, such as the 55-gallon drum. However, there are two notable distinctions between them.

Firstly, in the petroleum industry, the term “barrel” specifically refers to a 42-gallon oil barrel, which is a standard unit in that sector but not commonly used elsewhere. Secondly, in the alcoholic beverage industry, wooden barrels have traditionally been used for aging beverages, but now sterile stainless steel drums are more commonly used for transporting and fermenting products like wine, beer, and liquor.

Despite these distinctions, the term “barrel” has historically been used for both wooden and steel containers, partly due to linguistic tradition and to specify the contents. Apart from these exceptions, barrels and drums are essentially the same.

Applications

55-gallon drums are versatile containers, primarily used for storage and shipping. They are specifically designed to meet the international trade standard volume. Beyond these common uses, reconditioned 55-gallon drums can be repurposed as trash bins, compost bins, rain barrels, borders, and flotation devices.

Additionally, these drums come in 30, 40, and 20-gallon sizes and find applications across various industries, including agriculture, wastewater treatment, water storage, hazardous waste collection, pharmaceuticals, food and beverage, chemical processing, and petroleum.

History

Wooden barrels and drums have been utilized since at least the Middle Ages, primarily for storing beer and wine. By the 1700s, English colonists began using wooden barrels for importing and exporting goods. In the 1800s, with the American invention of whiskey, wooden barrels became essential for storing, shipping, and aging the spirit.

It wasn’t until the early 20th century that the 55-gallon steel drum was introduced. Around the same time, steel drums began to be used more widely. In 1905, two patents for the 55-gallon steel drum were granted to an employee of Nellie Bly’s Iron Clad Manufacturing Company in New York. These drums were developed to address issues with leaky and cumbersome metal drums previously used for transporting oil.

The 55-gallon steel drum gained prominence during World Wars I and II. In WWI, they were primarily used to ship sulfuric acid across Europe. During WWII, they were crucial for transporting airplane fuel and sometimes used to keep small vessels afloat.

After WWII, the use of 55-gallon steel drums expanded to include shipping gasoline and storing food. However, steel drums proved unsuitable for food storage due to rust and contamination risks. Consequently, the food industry transitioned to fiber drums, which are rust-resistant, lightweight, and disposable.

The next major advancement was HDPE, or high-density polyethylene, a synthetic plastic introduced in the 1960s. HDPE provided a cost-effective, rust-resistant alternative that outlasted fiber drums. Its chemical inertness made it ideal for food storage, leading to the establishment of FDA food-grade standards for 55-gallon plastic drums.

Today, plastic remains the primary material for food-grade drums, though the range of plastics available has expanded since the 1960s. Steel and fiber drums are still widely used, particularly for non-food-grade applications. Modern manufacturers are now focusing on both product effectiveness and sustainability.

Design

Production Process

Manufacturers use different methods to produce drums based on the material. For instance, they create metal drums through roll forming and welding, while plastic drums are typically made using blow molding. Fabric drums, on the other hand, are simply assembled. The production lines for these drums include equipment such as body makers, disc cutting machines, lid fixing machines, and ring fixing machines.

Given that these bulk containers often hold liquids, manufacturers of steel and plastic 55-gallon drums incorporate corrugations, or reinforcing rings, to strengthen their products. These corrugations, located at the top, bottom, and one-third of the way from the bottom, help reinforce the drum’s sides and prevent puncturing or denting during handling.

Materials

The choice of material for drum fabrication depends on the drum’s intended size and application. Common materials include steel, plastic, and fiber. Steel drums can be made from stainless steel, carbon steel, or cold-rolled steel. Plastic drums are often made from HDPE, polyvinyl chloride (PVC), polystyrene, and nylon, making them suitable for containing chemicals, lubricating oils, and solids and liquids of varying viscosity. Fiber drums, a more cost-effective alternative to steel drums, are typically made from dense paper or fiberboard.

Considerations and Customization

While drums are largely standardized, manufacturers can customize 55-gallon drums in various ways. Customization options include custom bung hole placement, additional bung holes, painting, and custom labeling.

Features

Steel, fiber, and plastic 55-gallon drums function similarly by remaining stationary. However, they differ in how users fill and access their contents. Some drums have a closed top that cannot be removed, while others have an open top that can be lifted. For closed top drums, users pour in and access the contents through a bung hole, which can be sealed with a plug. Open top drums allow users to lift the cover and access the contents by dumping, scooping, or pouring.

Workers have a few methods to move drums. They can stack the drums on pallets and transport them with a forklift. If the drums have reinforced sides, they can be tipped onto their side and rolled for short distances. Alternatively, the drums can be tipped at an angle and rolled along the edge of their bottom lid.

Types

All 55-gallon drums can be categorized as either closed head or open head types.

Closed head drums, also known as tight head drums, feature a fixed lid with a small opening (a bung hole) for pouring out the drum’s contents. Open head drums have a removable head.

Numerous drums fall under these two categories. Read on to learn more about some of them.

Water barrels: These are used to store and collect water, often fixed to the rooftops of industrial buildings and connected to ductwork. Water drums are also used for collecting and storing runoff and rainwater. Plastic is the most common material for these barrels due to its natural resistance to the elements.

Hazardous Waste Containers: These store chemical waste that cannot be disposed of through drains or trash. Hazardous materials include gasoline, disinfectants, grease, fertilizers, ceramic glazes, caustics, aerosol cans, nitric oxide, and similar substances. Hazardous waste containers can include various drum types such as 55-gallon plastic drums, 55-gallon steel drums, salvage drums, and chemical drums.

Used Drums: Also called reconditioned drums, these include used plastic, fiber, and steel drums. They are considered “green” because the reconditioning process involves stripping and flushing out the drum for continuous use. This process safely removes hazardous waste from used hazardous waste containers more effectively than other methods.

30-gallon steel drums: Commonly used for non-bulk applications like containing food products. A drawback is that steel barrels are prone to rusting when exposed to the elements, leading many businesses to favor rust-proof plastic drums.

Steel Drums: Often referred to as fuel drums, they are used to contain hazardous materials such as fragrances, pharmaceutical substances, and flammable chemicals. Stainless steel is used in anti-corrosive and sanitary applications due to its corrosion-resistant and sterile properties.

Plastic Drums: Highly durable yet lightweight, they are often available in a blue color, leading to the nickname “blue barrels.” Plastic drums are used for storing powders and caustic and acidic liquids.

Fiber Drums: Most frequently used to transport food products that need to be frozen or refrigerated, such as ice cream or cheese. Fiber drums are recommended for storing solid or dry materials. They are stackable, heat-resistant, and more easily recyclable than any other type of drum.

Advantages

There are numerous reasons to appreciate 55-gallon drums. They are affordable and readily available. Additionally, they are environmentally friendly; not only can they be recycled, but they can also be repurposed. With proper cleaning and approval, they can be reused for industrial applications. They can also serve as barriers, trash bins, rain barrels, and floating devices, among other uses. Finally, 55-gallon drums are durable, easy to transport, and stackable.

Accessories

Beyond the various types of drums, there is also a broad selection of drum accessories. One such accessory is a drum pump, a pneumatic device that fits into the opening of a drum. Drum pumps are often used to transfer plastisols from industrial drums to dip molding tank reservoirs.

Standards

The standards for your 55-gallon drums vary based on your application, industry, and location. For example, drums used for international trade must comply with UN (United Nations) regulations. If the drums are transported on U.S. roadways, they must meet DOT (Department of Transportation) standards.

Other industries with specific requirements include military and defense, food and beverage, and healthcare. If you’re unsure about which standards apply to your drums, consult with industry experts or relevant local authorities.

Things to Consider

No matter your application, sourcing your 55-gallon drums from a reputable distributor who prioritizes your needs is crucial. To find a trustworthy drum manufacturer, refer to the company profiles detailed on this page. Each listed company has a proven track record of reliability. Learn more about them by browsing their profiles.

As you review the options, consider your specific requirements. Identify the suppliers that best meet your criteria and narrow it down to three or four promising candidates. Request quotes from these suppliers and discuss your budget, standard requirements, timeline, and delivery preferences. After evaluating their responses, compare their offers to make an informed decision and get started with the supplier that best fits your needs.

Check out our Plastic Pallets website

55 Gallon Drums

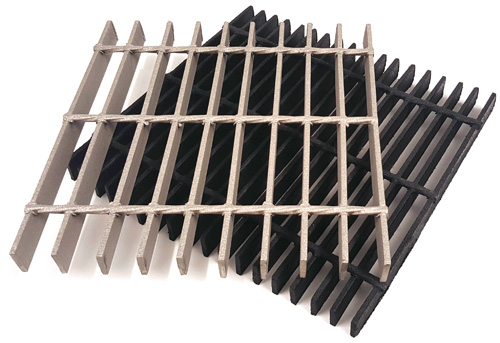

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services