Burn barrels are used for burning various types of waste, including yard waste, paper, cardboard, and other materials that can be safely burned. The use of burn barrels can be traced back to early settlements in rural areas. These barrels were typically made of metal and used to dispose of household waste, crop residues, and other debris. Over time, the design of burn barrels has evolved, with some modern versions including ventilation holes and a perforated lid for improved airflow. However, the use of burn barrels has also become more regulated in many areas due to safety concerns, environmental issues, and legal restrictions. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

Since 1947, General Container has specialized in a mixture of 55 gallon drums, a full line of boxes, shipping supplies and thousands of other industrial packaging and container products. This industry leader has the market's most knowledgeable customer service reps, a vast product offering, no minimum order, online ordering and volume discounts. Contact us today for more information.

Since 1918, James T. Warring Sons has been distributing new and reconditioned industrial drums, steel drums, fibre drums, plastic drums and industrial containers. We also offer plastic barrels and other products for nursery applications, as well as oak kegs and barrels for the winery industry.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

More Burn Barrel Manufacturers

How Burn Barrels Work

When burned properly, the waste and debris placed inside a burn barrel will combust and turn to ash. The efficiency of combustion can be affected by various factors, including the type of waste being burned, the amount of oxygen available, and the temperature of the fire. To prevent hazardous situations during use, it is important to follow safety guidelines, such as avoiding the use of accelerants and keeping a safe distance from the barrel during operation.

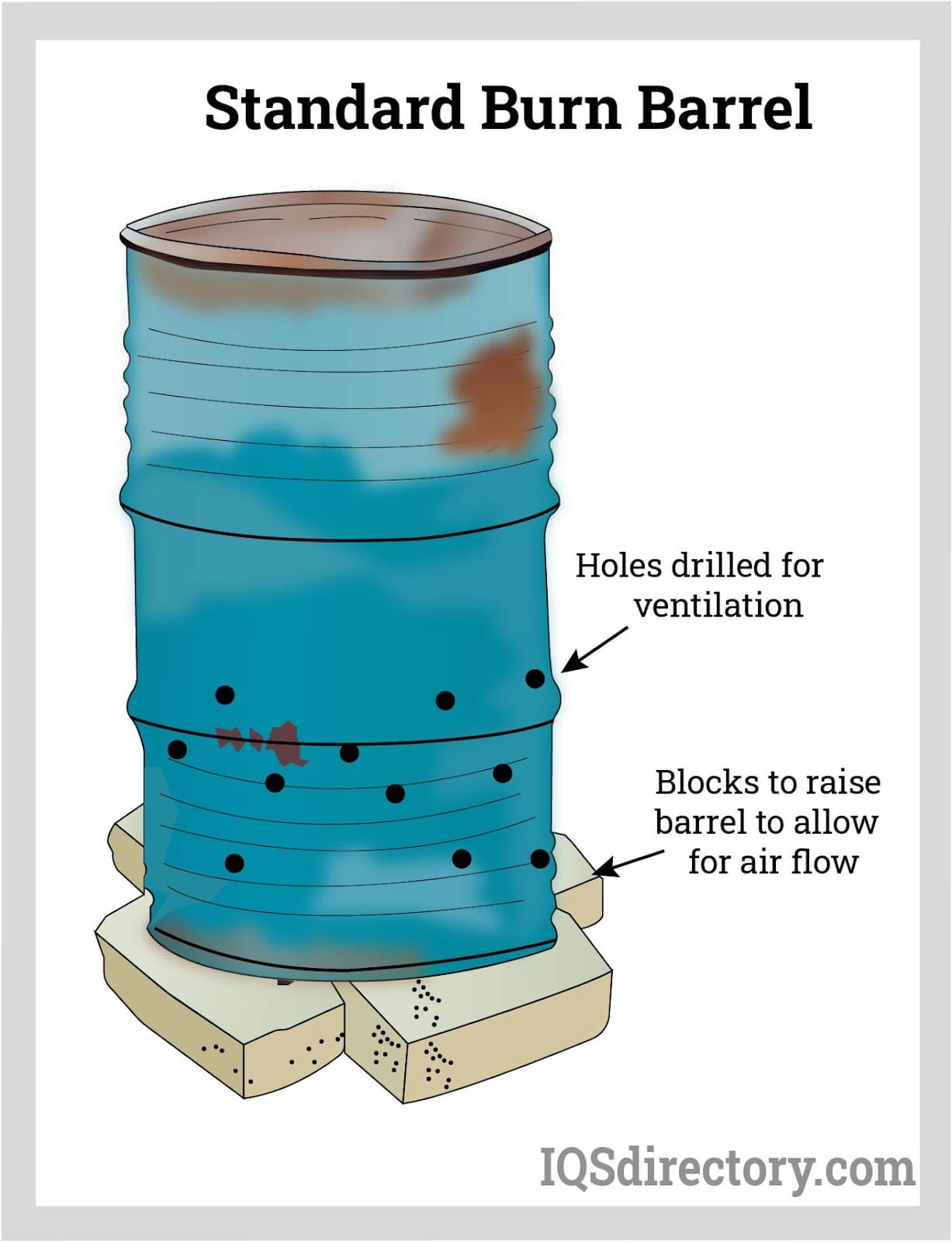

Construction of Burn Barrels

The construction process typically involves cutting ventilation holes into the sides of the barrel, creating a perforated lid for improved airflow, and adding a sturdy base to prevent tipping. It is important to take safety precautions during the construction process, such as wearing gloves and eye protection. Burn barrels can be constructed from a variety of materials, including various metals, plastics, ceramics, and concrete blocks. More information on these different material choices will be examined below.

Metal burn barrels: Metal burn barrels are the most common type of burn barrel. They are typically made of steel or aluminum to be durable and long-lasting. Metal burn barrels are easy to clean and maintain, and they can withstand high temperatures. They are also resistant to rust and corrosion, making them ideal for use in humid or wet conditions. Metal burn barrels may be chosen over other materials because they are affordable and readily available.

Plastic burn barrels: Plastic burn barrels are becoming increasingly popular. They are lightweight and easy to move around, making them ideal for use in small spaces or for people who need to move their burn barrel frequently. Plastic burn barrels may be chosen over other materials because they are affordable and easy to find.

Ceramic burn barrels: Ceramic burn barrels are less common but are sometimes used for decorative purposes. They are often designed to look like traditional clay pots or urns and can add a touch of style to an outdoor space. Ceramic burn barrels may be chosen over other materials for their aesthetic appeal.

Concrete burn barrels: Concrete burn barrels are heavy and durable, making them ideal for use in windy conditions. They can also withstand high temperatures and are resistant to weathering. Concrete burn barrels may be chosen over other materials for their durability and longevity.

Disadvantages of Burn Barrels

While burn barrels may seem like a convenient and cost-effective way to dispose of waste, they can also have negative consequences. One major concern is the environmental impact of burning waste, which can release harmful pollutants into the air and soil. Additionally, burn barrels can be a safety hazard, as they have been known to tip over, cause fires, and release toxic fumes. Finally, many areas have legal restrictions or limitations on the use of burn barrels, making them illegal in some cases.

Benefits of Burn Barrels

Despite the potential drawbacks, burn barrels do offer many benefits, including:

Efficient waste disposal: Burn barrels can be a convenient and efficient way to dispose of waste, as they can handle a variety of materials and reduce them to ash.

Cost-effective: Burn barrels can be a cost-effective alternative to hiring professional waste disposal services, which can be expensive.

Versatile: Burn barrels can be used in a variety of settings, including residential, agricultural, and industrial environments.

Applications of Burn Barrels

Burn barrels exhibit their usefulness in a variety of settings as described below.

Residential Use: In residential settings, burn barrels can be used to dispose of non-toxic materials such as leaves, branches, and paper. They can also be used to burn sensitive documents and confidential papers.

Agricultural use for animal waste and crop residue disposal: In agricultural settings, burn barrels can be used to dispose of animal waste, such as cow manure, and crop residues, such as straw and corn stalks. Burn barrels can also be used to control weeds and pests.

Industrial use for hazardous waste management: Burn barrels can be used in industrial settings for the disposal of hazardous waste materials, such as chemicals, solvents, and other toxic materials. However, it is important to follow safety guidelines and legal regulations when using burn barrels for hazardous waste disposal.

Choosing the Right Burn Barrel Supplier

To ensure you have the most positive outcome when purchasing from a burn barrel supplier, it is important to compare several companies using our directory of burn barrel suppliers. Each burn barrel supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each burn barrel business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple burn barrel companies with the same form.

55 Gallon Drums

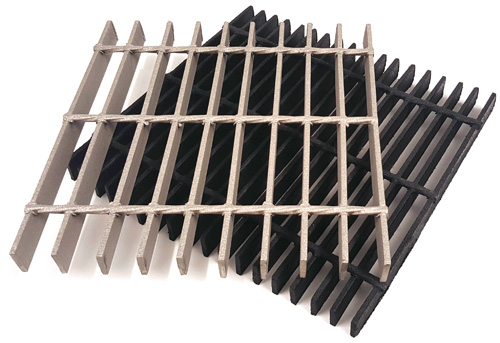

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services