Plastic drums are the most versatile equipment found in warehouses for the storage and transporting of materials. Plastic drums are generally blue with a spherical shape, and their sizes may vary accordingly. These drums are used in many industries for the storage of hazardous materials as well as for foodstuff. Plastic drums are made from a material known as HDPE, a malleable and rigid material that can withstand high temperatures and chemicals. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

Since 1947, General Container has specialized in a mixture of 55 gallon drums, a full line of boxes, shipping supplies and thousands of other industrial packaging and container products. This industry leader has the market's most knowledgeable customer service reps, a vast product offering, no minimum order, online ordering and volume discounts. Contact us today for more information.

Since 1918, James T. Warring Sons has been distributing new and reconditioned industrial drums, steel drums, fibre drums, plastic drums and industrial containers. We also offer plastic barrels and other products for nursery applications, as well as oak kegs and barrels for the winery industry.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

More Plastic Drum Manufacturers

The sizes of plastic drums vary according to the needs of various industries. These sizes can range from 30-liter barrels up to 220-liter barrels. The bigger drums can be lifted easily with forklifts; however, the smaller ones have side handles that allow them to be moved and lifted by hand.

Types of Plastic Drums

Two primary types of plastic drums that are used in industrial packaging. These are:

Open-Head

Open-head plastic drums have a removable lid on the top, making pouring contents easier. These plastic barrels are sealed tightly with the help of steel clamps so they can be left in storage.

Tight-Head

Tight-head plastic barrels are more like closed-head drums, but the main difference is that these are sealed on both sides to avoid spillage. In addition, a nozzle is attached to the body of the barrel for easy emptying. However, the pouring process is difficult in these barrels, but these are quite secure in terms of spillage of hazardous chemicals.

Types of Plastic Used for Plastic Drums

Plastic drums are generally made from different types of plastic, such as HDPE, PVC, nylon, and polystyrene. Each material has different characteristics and depends on the type of product to be stored in the drum.

High-Density Polyethylene

- Plastic drums can be made from a thermoplastic polymer called high-density polyethylene or HDPE.

- HDPE is the most versatile plastic material and is used in various applications, such as plastic bottles, milk jugs, shampoo bottles, cutting boards, and pipes.

- This polymer has a high melting point and impact resistance with great tensile strength.

- HDPE is malleable and easily meltable, which aids in the molding process.

- HDPE has a high corrosion resistance.

- High-density polyethylene is easily recyclable, strong, lightweight, and chemically resistant.

Polyvinyl Chloride

- It is a synthetic resin that is made from the polymerization of vinyl chloride.

- PVC is rigid, strong, and resistant to flame.

- PVC drums are very popular in industries for storing flammable and toxic substances.

Nylon

- Nylon is used to make plastic drums because it is non-reactive, has low moisture absorption, and has chemical resistance.

Polystyrene

- Polystyrene is also a thermoplastic made from the polymerization of styrene.

- It is popular in manufacturing polystyrene cups, plates, containers, and trays.

Manufacturing Processes for Plastic Drums

Three processes are used to manufacture plastic drums. These are:

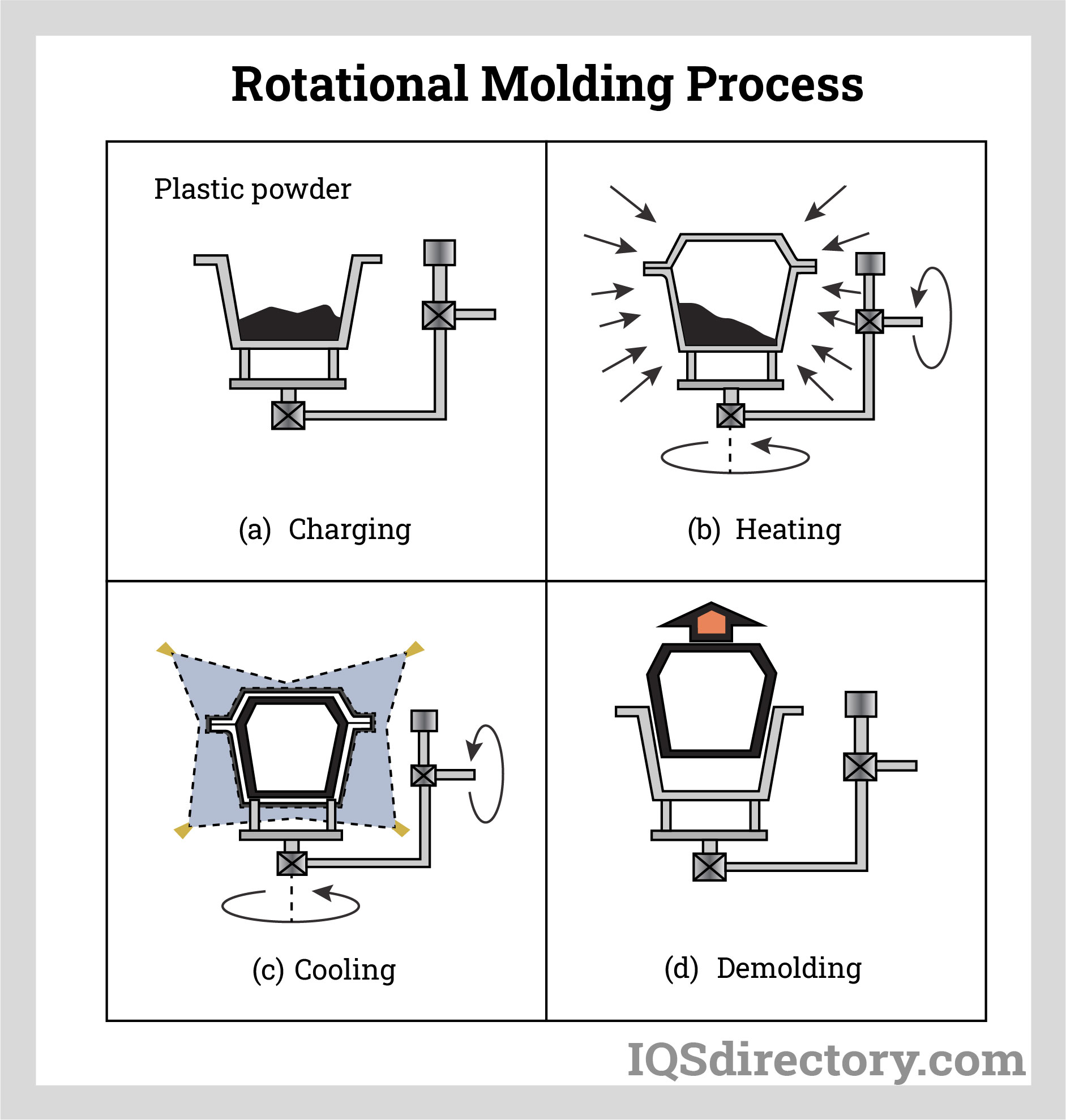

Rotational Molding

- Rotational molding is a high-temperature, low-pressure plastic forming process.

- It is used for making large and hollow parts and is cheaper than any other method.

- The first step is to pour a powdered polymer into the mold.

- It is then rotated in an oven at a high temperature for the polymer to be melted completely.

- It is then cooled down with the help of a fan, which takes about ten minutes.

- After cooling, the part is then removed from the mold.

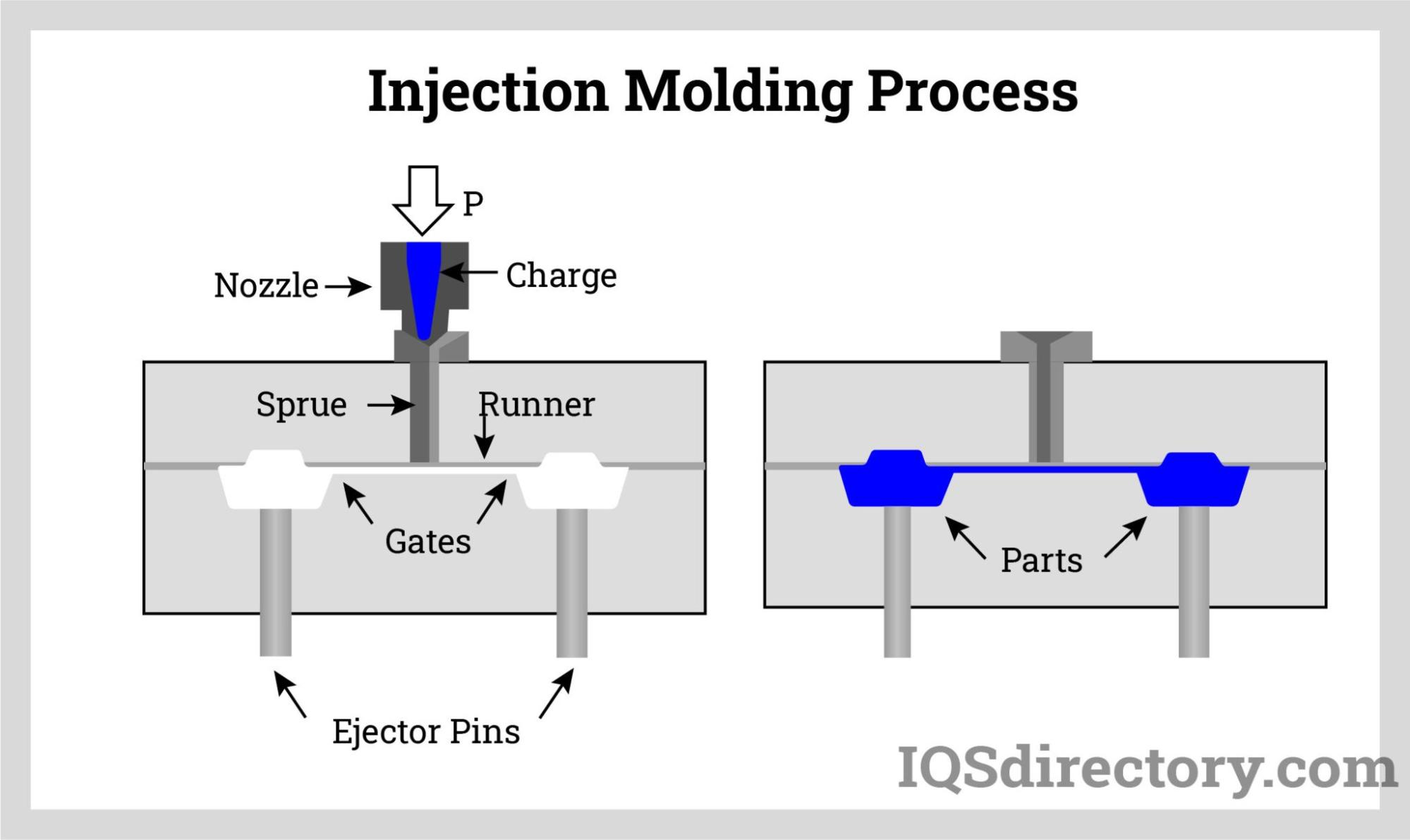

Injection Molding

- It is a plastic manufacturing process in which molten materials are injected into molds.

- The machine consists of three parts: the injection unit, the mold, and the clamps.

- The part’s materials are fed into the heated barrels, where these are mixed and then injected into the mold cavity.

- It is then cooled down and hardened into the configuration of the cavity.

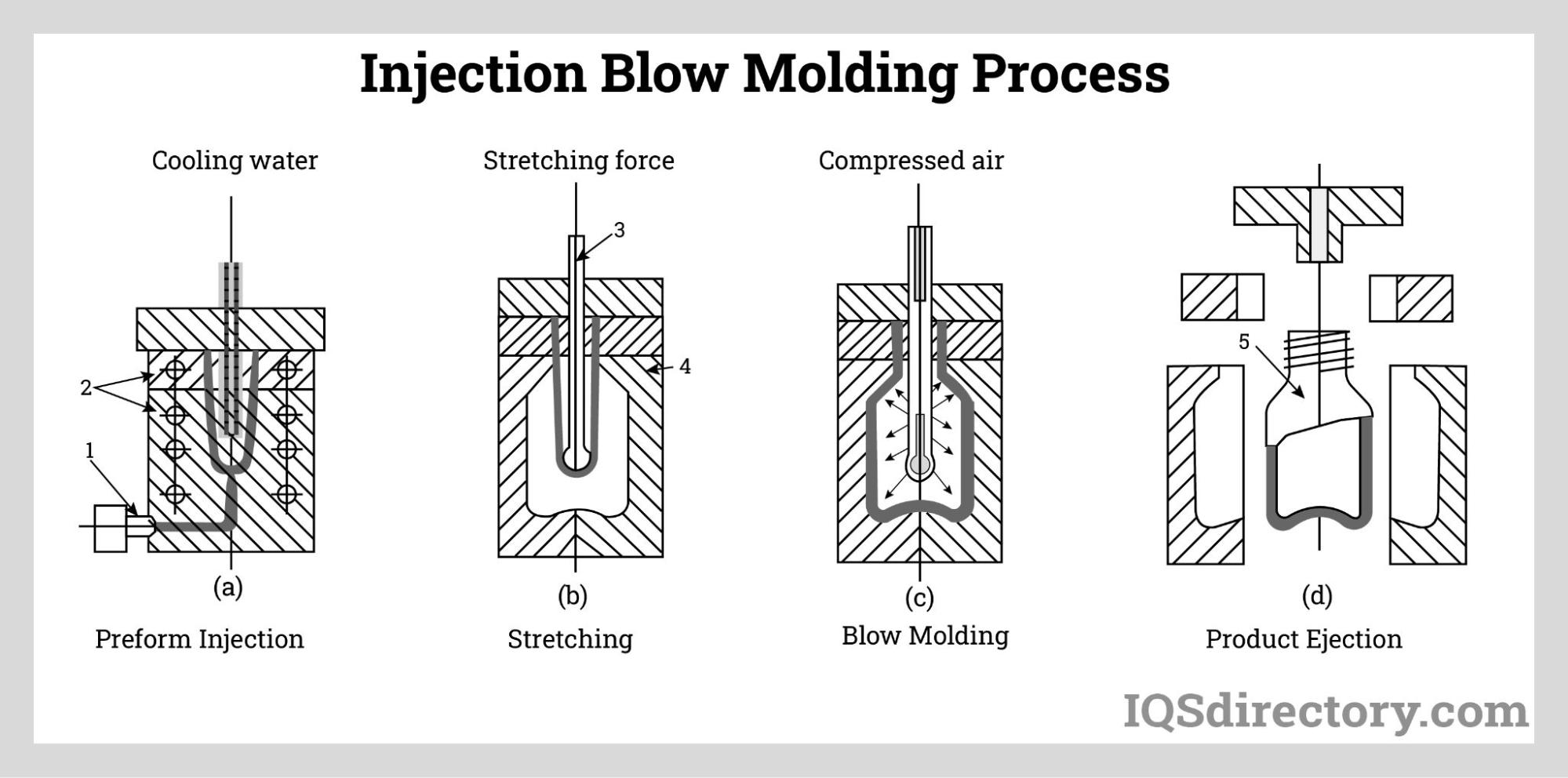

Injection Blow Molding

- The injection blow molding process produces hollow objects such as bottles, jars, and plastic drums.

- The injection blow molding machine has an extruder barrel and a screw assembly for melting the polymer.

- The melted polymer is then injected into the heated and hollow molds through the nozzles.

- The compressed air is then blown into the mold, which helps it take the cavity’s shape.

- The last step is the rods are then rotated in the ejection mode from where the cooled part is ejected.

Applications of Plastic Drums

- Plastic drums are used for storing liquids such as rainwater or freshwater.

- Plastic drums are also used in the chemical industry for storing hazardous chemicals.

- The drums are also used for storing medicines.

- Plastic drums are also used in the food industry for storing grains, dry condiments, and spices.

- The oil industry also uses plastic drums for storing lubricants and oils.

Choosing the Right Plastic Drum Manufacturer

To make sure you have the most productive outcome when purchasing Plastic Drums from a Plastic Drum Manufacturer, it is important to compare at least 5 or 6 Companies using our Plastic Drums directory. Each Plastic Drum Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Plastic Drum business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Plastic Drum companies with the same message.

55 Gallon Drums

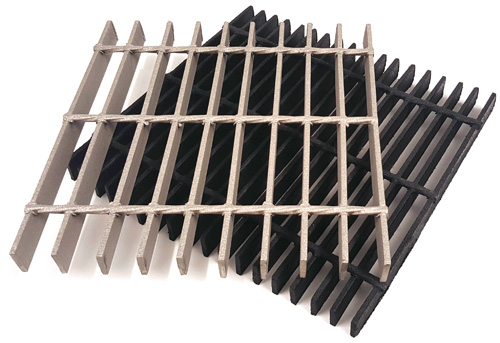

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services