Reconditioned drums can be either plastic or steel drums that have undergone the reconditioning process to ensure optimum repeat use. Whereas in drum reconditioning, the drum is not often altered with new materials or parts (except for the lid), remanufactured drums must undergo a much more intense process, changing many aspects of the old drum. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

Since 1947, General Container has specialized in a mixture of 55 gallon drums, a full line of boxes, shipping supplies and thousands of other industrial packaging and container products. This industry leader has the market's most knowledgeable customer service reps, a vast product offering, no minimum order, online ordering and volume discounts. Contact us today for more information.

Since 1918, James T. Warring Sons has been distributing new and reconditioned industrial drums, steel drums, fibre drums, plastic drums and industrial containers. We also offer plastic barrels and other products for nursery applications, as well as oak kegs and barrels for the winery industry.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

More Used Drum Manufacturers

More cost-effective than newly manufactured drums, used drums are utilized in wide-spread industries such as: industrial manufacturing, for storage and transport of various chemicals required for machinery and manufacturing processes; automotive and aerospace, for material handling of oils and other chemicals required for proper maintenance and functioning of vehicles; medical and pharmaceutical, for material handling of potentially hazardous materials; and food and beverage, for proper sanitary handling of food and liquids of various viscosities.

Used drums are still held to stringent material handling standards, especially by United Nations (UN) and the International Organization for Standardization (ISO), for quality assurance.

In order for a drum to be re-used, it must undergo inspections to ensure that it will be safe for repeat use after either reconditioning or remanufacturing processes. Once the drums have been approved, they may undergo one of these two processes for re-use. For reconditioning, there are five main steps. The first step is leak testing, which is a visual and technical test to ensure that the drum will not leak. The next step is dent removal, after a visual and technical inspection to ensure a seamless, hopefully flawless, reconditioned drum.

After these two tests, the next step is to remove any coating from the drum through chemical and non-chemical measures. After the coating removal follows an inspection and re-fitting of all drum closures, such as the lid and non-integral gaskets. The last step is re-painting and marking of the drum for use. An additional step may be included for steel drums, referred to as chime straightening.

For the remanufacturing process, there are four different types of remanufacturing mainly used. The first type is conversion of a UN 1A1 drum to a UN 1A2 drum. The second type involves the replacement of an integral structural component. The third type requires the manufacturing of one or more new rolling hoops for the drum. The fourth type is fairly broad, and involves the conversion of drums from one specification to a different specification.

55 Gallon Drums

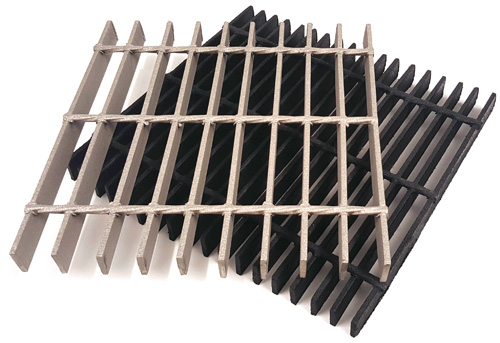

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services