Water is essential for life, and access to clean water is vital in emergency situations. Water barrels are an excellent solution to store water for various purposes. A typical water barrel is a 55-gallon drum made of plastic, metal, or wood. In this article, we will discuss the different materials, design variations, benefits, and applications of water barrels, as well as any considerations regarding their use. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

Since 1947, General Container has specialized in a mixture of 55 gallon drums, a full line of boxes, shipping supplies and thousands of other industrial packaging and container products. This industry leader has the market's most knowledgeable customer service reps, a vast product offering, no minimum order, online ordering and volume discounts. Contact us today for more information.

Since 1918, James T. Warring Sons has been distributing new and reconditioned industrial drums, steel drums, fibre drums, plastic drums and industrial containers. We also offer plastic barrels and other products for nursery applications, as well as oak kegs and barrels for the winery industry.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

More Water Barrel Manufacturers

Materials Used for Water Barrels

There are three main types of water barrels: plastic, metal, and wooden. Plastic water barrels are the most common because they are affordable, lightweight, and easy to handle. Plastic barrels are also resistant to corrosion and rust. Metal water barrels are durable and sturdy, making them ideal for outdoor applications. They are resistant to impacts and punctures, making them a great option for heavy-duty use. Wooden water barrels are a traditional option and can add aesthetic appeal to gardens and outdoor spaces. They are typically used for rainwater harvesting and decorative purposes.

Design Variations in Water Barrels

Water barrels come in different designs that suit different applications. Open top water barrels are ideal for outdoor use and easy to fill with a hose or bucket. They are used for rainwater harvesting, irrigation, and livestock watering. Closed top water barrels have a sealed top that prevents debris and contaminants from entering. They are ideal for emergency water storage and long-term water conservation. Bung-type water barrels have a threaded opening and closing mechanism that provides an airtight seal, making them ideal for storing chemicals, fuels, and other hazardous materials; they are often used for long-term water conservation and emergency water storage, ensuring that clean water is readily available during natural disasters or other emergencies.

Considerations Regarding Water Barrels

Water barrels require regular cleaning to prevent contamination. They can be challenging to clean, especially if they have a narrow opening. Additionally, water barrels can be heavy when filled with water, making them difficult to move or transport. Lastly, the quality of the water stored in water barrels can be compromised if the barrels are made of low-quality materials or if they are not properly maintained.

Benefits of Water Barrels

Despite these considerations, water barrels offer several benefits, including emergency preparedness, water conservation, and cost savings. In an emergency situation, having a water barrel on hand can provide access to clean water when municipal water systems are compromised. Water barrels can also be used to collect and store rainwater, which can be used for irrigation, washing cars, and flushing toilets, among other uses. This can save homeowners money on their water bills while conserving water resources. Additionally, purchasing water in bulk and storing it in water barrels can be a cost-effective alternative to buying individual bottles or jugs.

Applications of Water Barrels

Water barrels have a wide range of applications, including:

Gardening and Irrigation

Water barrels are great for storing rainwater, which can be used for watering plants and gardens. This can reduce water usage and save homeowners money on their water bills.

Livestock Watering

Water barrels can be used to provide clean water for livestock. They can be filled with water and then gravity-fed into a watering trough or used with a gravity-fed watering system.

Rainwater Harvesting

Water barrels can be used to collect and store rainwater, which can be used for various purposes, including flushing toilets, washing clothes, and watering gardens. This can save homeowners money on their water bills while conserving water resources.

Emergency Water Storage

Water barrels are an essential tool for emergency preparedness, providing access to clean water during natural disasters or other emergencies.

Camping and Outdoor Recreation

Water barrels can be used to provide clean water in remote locations, making them ideal for camping and other outdoor activities.

Construction Sites

Water barrels can be used to provide water for construction sites where access to water is limited.

Firefighting

Water barrels can be used to supply water for firefighting efforts in rural areas where there are no fire hydrants.

Industrial Applications

Water barrels can be used to store water, chemicals, fuels, and other hazardous materials in industrial settings.

Food and Beverage Production

Water barrels can be used to store clean water for food and beverage production processes, such as brewing beer or making wine.

Off-Grid Living

Water barrels can be used in off-grid living situations where access to municipal water is limited, providing a sustainable and cost-effective water source.

Choosing the Correct Water Barrel Supplier

To ensure you have the most productive outcome when purchasing water barrels from a water barrel supplier, it is important to compare several companies using our directory of water barrel suppliers. Each water barrel supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each water barrel business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple water barrel companies with the same form.

55 Gallon Drums

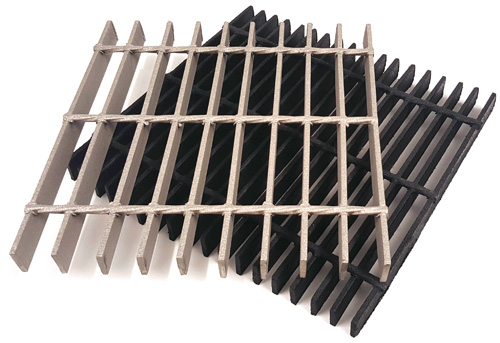

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services